Leading Innovation with 3D Printing

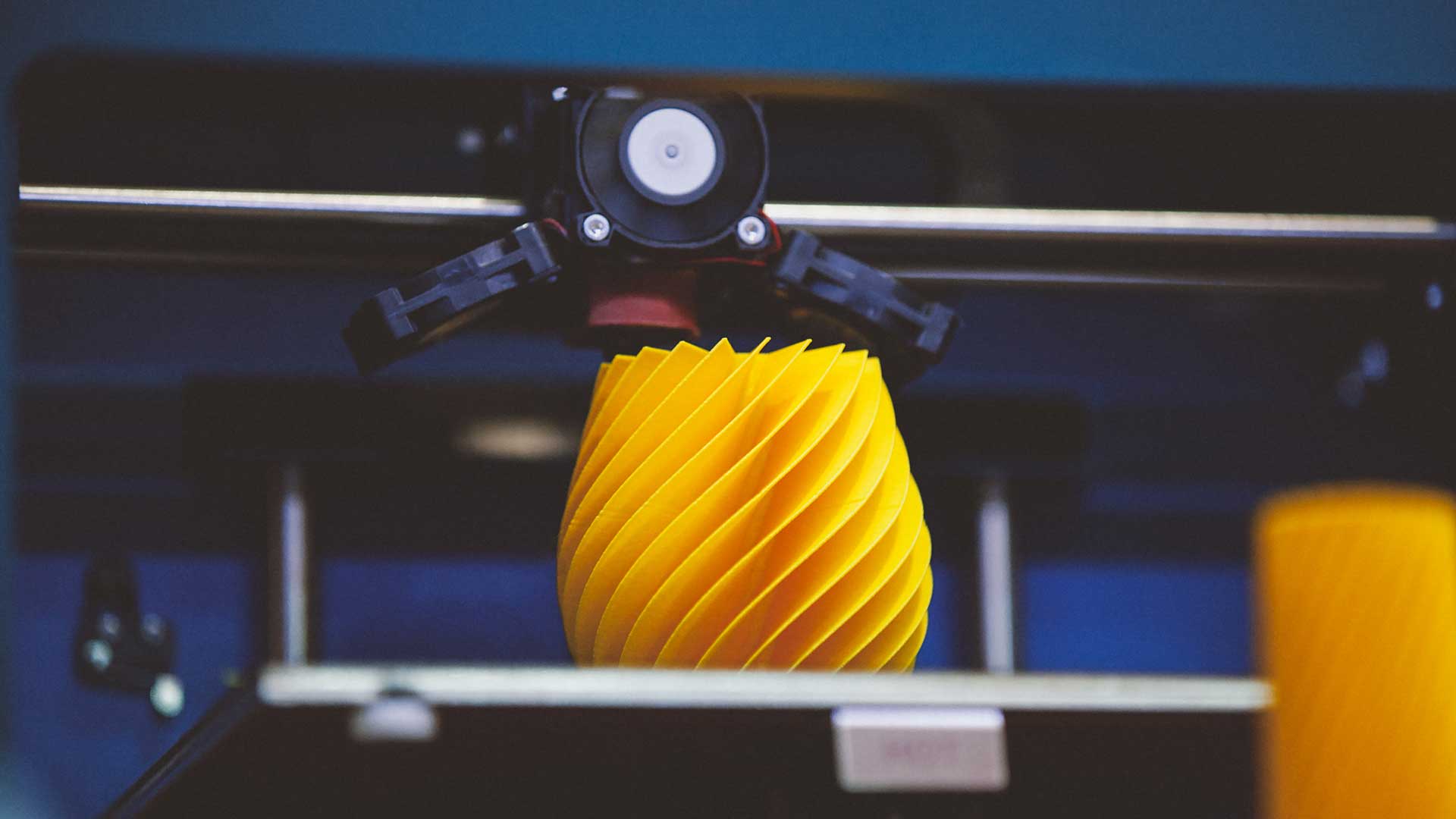

In another industry-leading move, Forte continues its legacy of innovation with the implementation of a first-of-its-kind 3D printer. Forte’s 3D printer is impressively one of the largest west of the Mississippi River and drastically reduces fabrication time. Used to print in-house tooling, single part molds, or themed elements that would traditionally require hand-carving, 3D printers such as these will soon be commonplace in the industry.

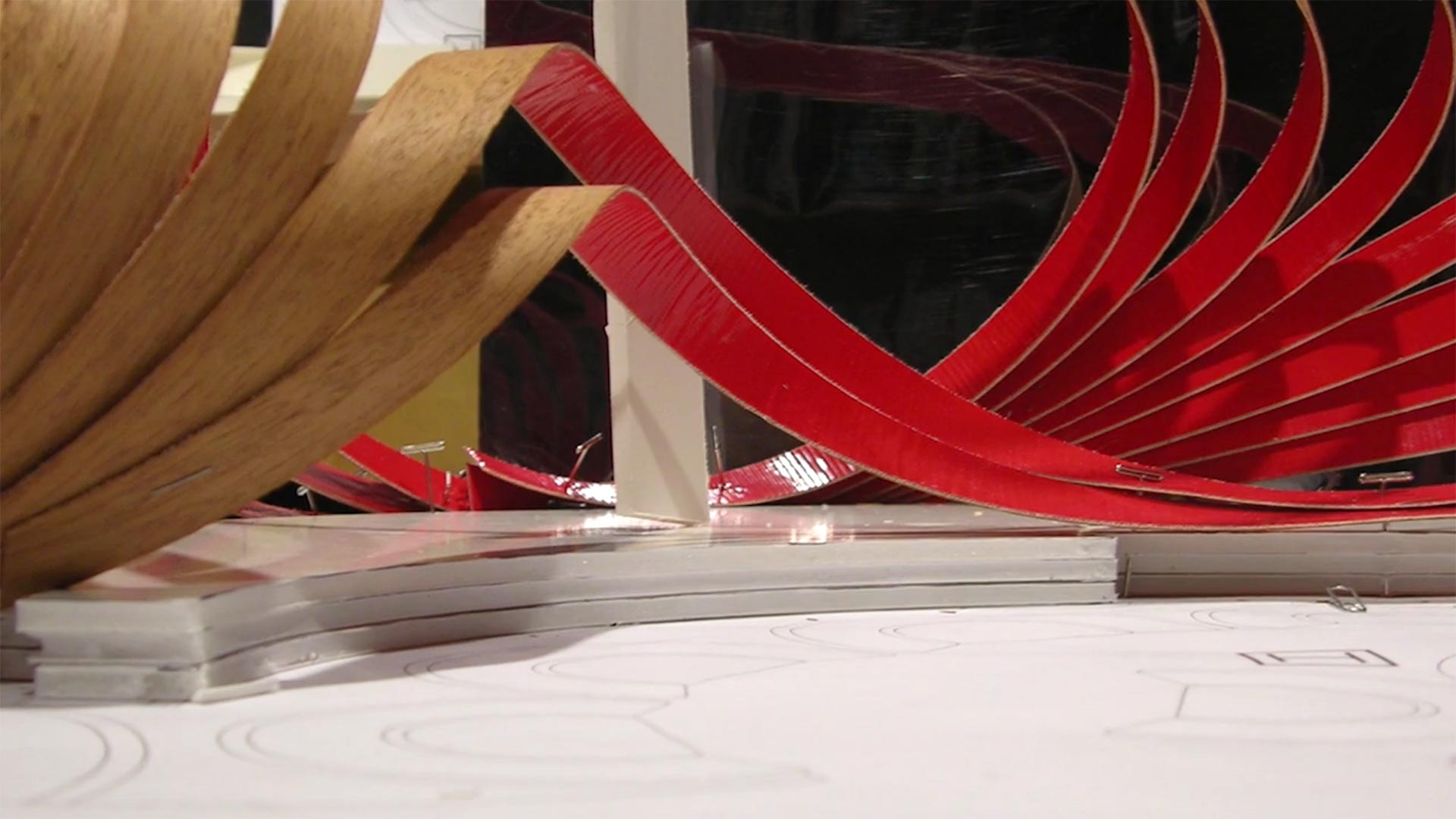

Before construction even begins, Forte can print a client’s project on a small scale, allowing the team to make efficient adjustments, visually communicate with clients unlike ever before, and save clients time and money. Scott Acton, Forte’s CEO, said: “It has also reduced conflict and made the process a lot more fun!” The 3D printer can print items as large as 4 ft x 5 ft x 6 ft and as much as 14 inches in height every hour. This allows for fast and accurate visual communication, events, entertainment, concept prototyping, and interior design solutions.

As 3D printing technology continues to advance, the ways it can be applied to construction will only develop further. It is even exciting that 3D printing will be a likely component of sustainable building methods in the future since there are currently companies that are in the development of 3D printers that can create entire structures out of recycled materials.

Forte’s ability to implement technological innovations sets the company apart from others, who may only rely on building methods of the past. Innovation is at the heart of Forte’s DNA, which they will continue to do as technology continues to progress.